High power fiber laser FO series ring mode

Adjustable Ring Mode (patented)

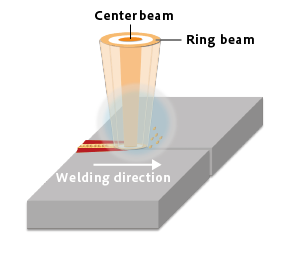

The beam irradiated from ARM is separated coaxially to Center and Ring and reaches the processed area. Each beam of Center and Ring is generated inside the oscillator without using external optical system and is transmitted to the exit port while maintaining beam quality.

Center + Ring

This completely new beam mode realizes advanced processing in welding, cutting and surface treatment, which never been a possible by conventional laser. Reducing a sputter during welding galvanized steel, drastic improvement of welding quality of aluminum materials, and other new processing technology are expected to be developed. A various combination of independently controllable laser in one beam brings you significant arm to your laser processing.

Processing application example

ARM solves problems such as sputtering and defects which occurs during welding processing on aluminum and galvanized steel.

Welding : Aluminum

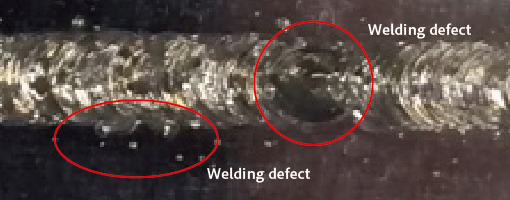

Welding process on aluminum materials by laser used to bring defects such as porosity(void) and undercut(thinning). In addition, vast amount of sputters generated during the process damages product itself and processing equipment. With ARM, we can solve these problems.

Comparison in movie(appearance of spatter generation)

Welding by FO

Welding by conventional laser

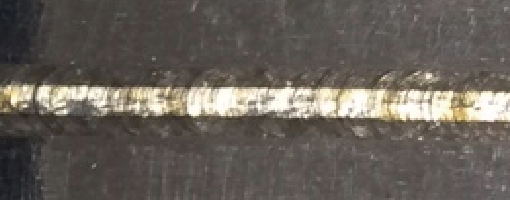

Comparison with images (weld surface)

Welding by FO

Material: Aluminum (1000 series)

Material: Aluminum (1000 series) Laser : Ring mode laser ARM

Welding by conventional laser

Galvanized steel sheet lap welding (no gap)

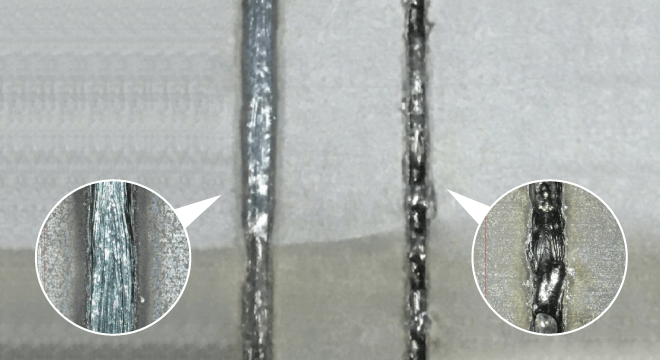

In lap welding of coating materials such as galvanized steel plate and galvalume steel plate, techniques are adopted in which materials are overlapped with gaps to avoid the occurrence of sputters and porosity (void). Adjustment of the beam profile by ARM enables high quality welding without any gap, then processes such as clearance management and post-treatment may be reduced.

Comparison in movie

- Welding by ARM

- Welding by conventional multimode laser

Comparison with images

- Surface of weld bead

Weld bead by ARM (left) and conventional laser (right)

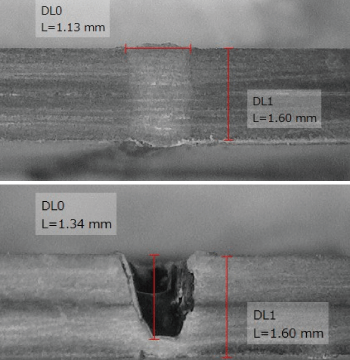

- Cross section of welded area

By ARM (top) and conventional laser (bottom)

Benefits of Center-Ring coaxial irradiation and independent control

- Optimizing processing conditions each for variety kind of materials

- Thanks to ring shape beam, there is no limitation on processing directionality

- Lap welding of galvanized steel (no gap)

- Reducing a sputter during welding processing

- Piercing and end point optimization

Demonstration guide

We will support you to verify processing performance and to find processing conditions by ARM in our demonstration facility.

Location

Papas Co., LTD, Aikawa Factory, Laser Center

357-10 Akikawa-cho, Aiko-gun, Kanagawa Prefecture 243-0301 •Odakyu Ebina Station → Ebina Eki NIshiguchi Bus Stop : Umi 01 Aikawa Bus Center Line

•Odakyu Ebina Station → Ebina Eki NIshiguchi Bus Stop : Umi 01 Aikawa Bus Center Line

→ Bus Stop: Aikawa Koko Iriguchi (about 40 minutes) About 5 minutes on foot after getting off the bus.

•JR Sagami Line: Kamimizo Station → About 20 minutes by Taxi

•JR Yokohama Line / Sagami Line / Keio Sagamihara Line: Hashimoto Station → About 35 minutes by Taxi

Person in charge: Odashima, MITSUI KNOWLEDGE INDUSTRY CO., LTD.

Contact Information

MITSUI KNOWLEDGE INDUSTRY CO., LTD.

Machinery 3rd Division, Machinery & Materials Unit

Tel:+81-3-6403-5945

e-mail:[email protected]

Sales:Shimada