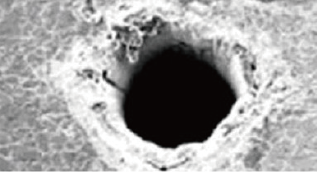

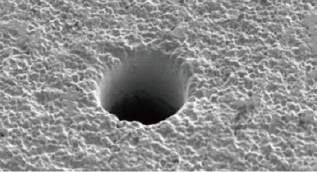

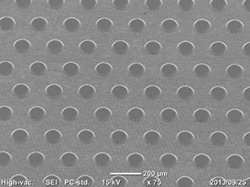

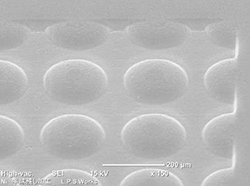

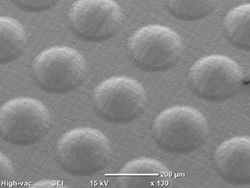

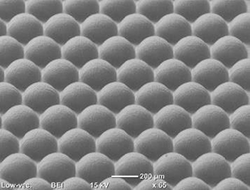

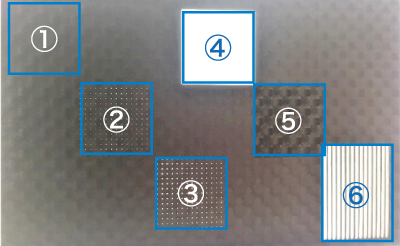

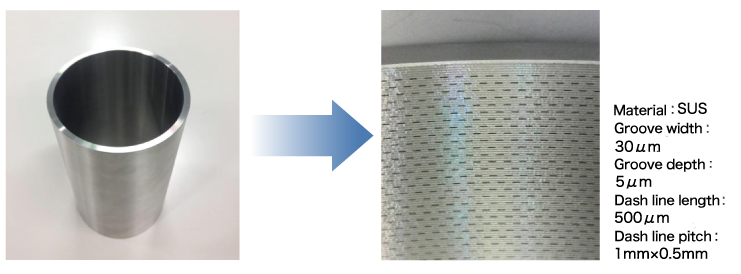

We provide precise and high-speed laser solutions for various applications such as micro-structuring, ablating,

cleaning, scribing, slitting, microfabricating, etc., by high-power ultra short pulse laser (maximum output: 1000 W)

and various optical units such as polygon scanner (maximum scanning speed: 200m/s).

【Advantages of our laser solutions】

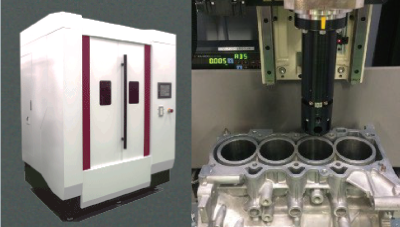

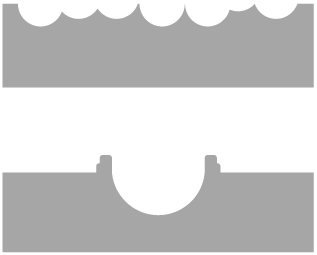

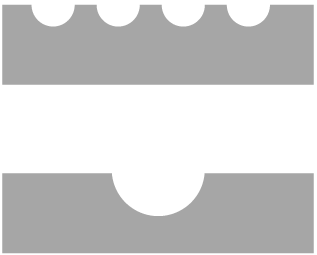

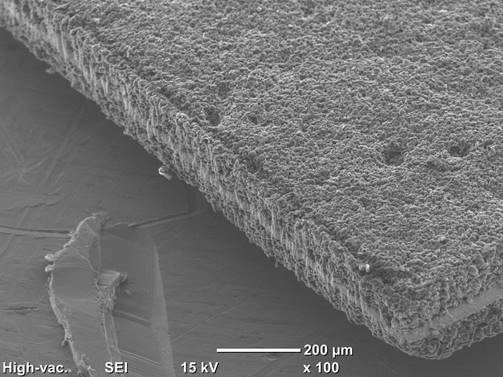

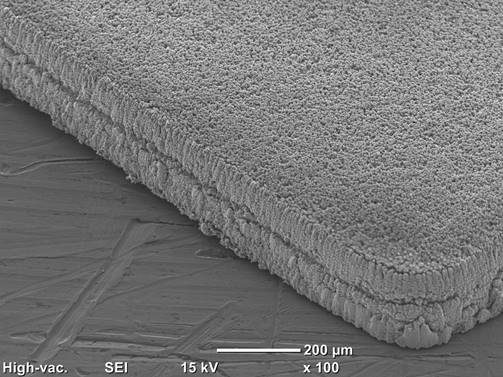

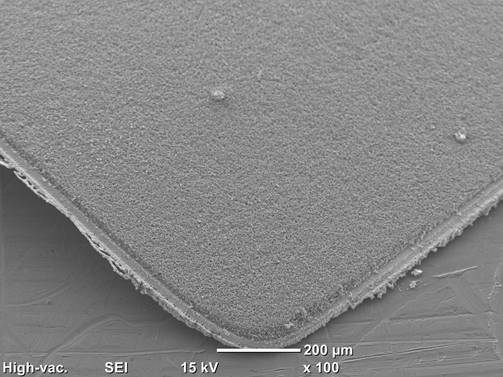

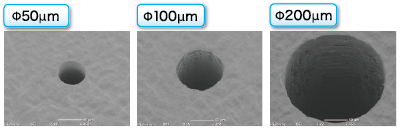

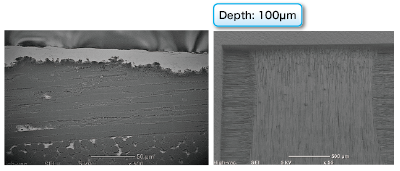

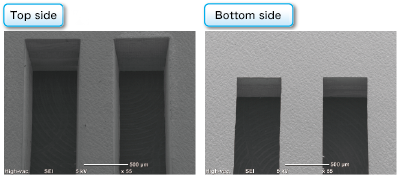

・Burrs and heat affected zones (HAZ) free process.

・Fine and high precise machining process at high speed.

・Various materials, such as metals, resins, ceramics, glass, composite materials, can be processed.