We have developed a roll-to-roll laser high-speed drilling machine for mass production that could not be realized with conventional Galvano mirrors and polygon mirrors.

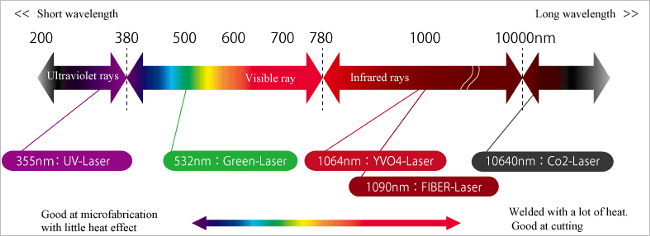

This machine is the only one in the world utilizing unique technology of original optical design (GHS), expertise for selecting the optimum laser oscillator and expertise for laser processing for roll-shaped films, which enables high-speed drilling of various films and foils.

Possible to process fine holes with a diameter of 10µm to 20µm.

Possible to process fine holes with a diameter of 10µm to 20µm.