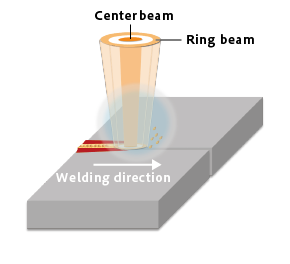

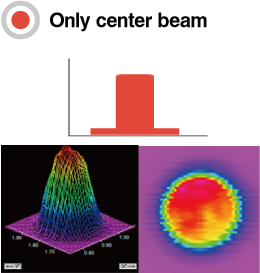

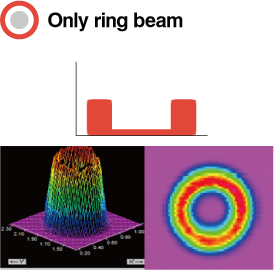

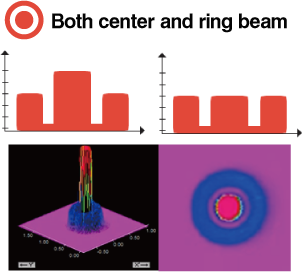

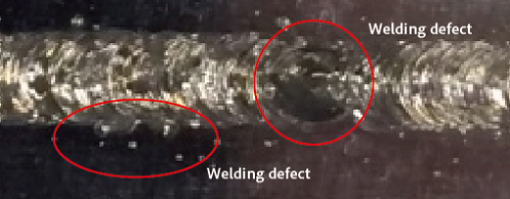

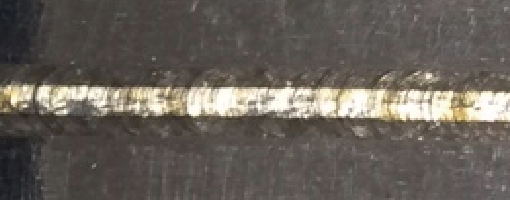

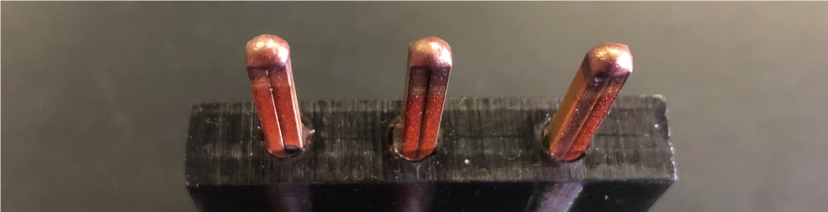

FO series ARM (Adjustable Ring Mode), which is a fiber laser we handle, has the beam for center and ring. Both beams are separated coaxially and reach the processed area. This beam mode is completely a new processing mode that could not be realized by conventional laser welding and cutting.

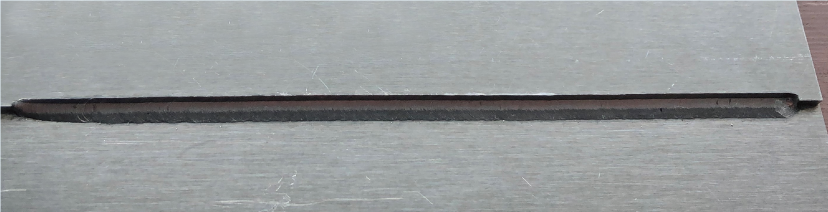

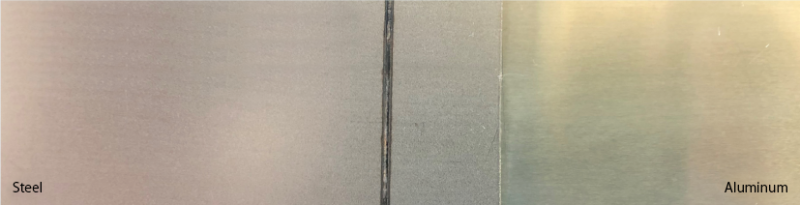

In addition to this laser oscillator, we could achieve sputter reduction during welding, dramatic improvement for the bead surface and improvement of welding strength by combining robots and optical heads under the optimum conditions for the target materials.

We will support you to verify processing performance and to find optimum conditions by ARM at our demonstration facility.

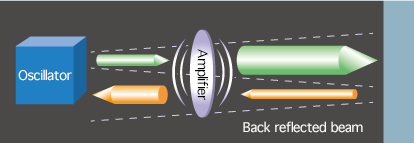

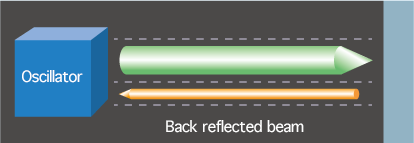

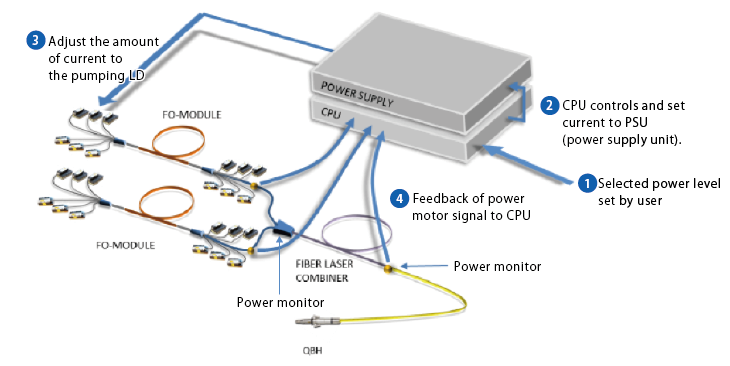

Oscillator generates high power laser without using amplifier.

Oscillator generates high power laser without using amplifier.

Automobile parts

Automobile parts Building materials

Building materials